Wuxi Plaswelding Machinery Co., Ltd. is specializing in the production of various types of plastic tube welding machines and welding machine parts and accessories. Rich experience, reliable hardware, and a professional after-sales team can provide you with the best plastic pipe welders for sale. We also provide international training and advice for plastic pipe welding machine for sale, and our customers know that high-quality industrial plastic tube welder solutions can be obtained anytime and anywhere.

Wuxi Plaswelding Machinery Co., Ltd was founded three years ago. But our general manager, Mr. David Yao has been focusing on the manufacturing and selling of butt welding machines for more than 16 years. Our engineers are also the best in this field.

Plaswelding can not only provide the best welding machines. We also provide spare parts for even our earliest units. Plaswelding machines are built to meet the ongoing productivity demands expected by our customers. Our mission is to ensure proper equipment on-site, Service and training are available to our clients regardless of their location. The company is accredited to ISO 9000. All products have CE certificates.

Our machines are now exported to more than 20 countries around the world. Like Thailand, Vietnam, UAE, Australia, Colombia, Mexico, South Africa, USA, etc. We would ensure the quality of the China automatic welding machine. Plaswelding is making efforts to ensure all manufacturing processes are to the highest standard of quality with the full support and co-operation of Plaswelding staff.

We are very strict with suppliers, including the supplier's corporate qualification, production capacity, quality system control, raw material quality assurance, technical strength, supply cycle, transportation and freight, as well as future quality problems, response speed, service status and evaluation of cooperation results.

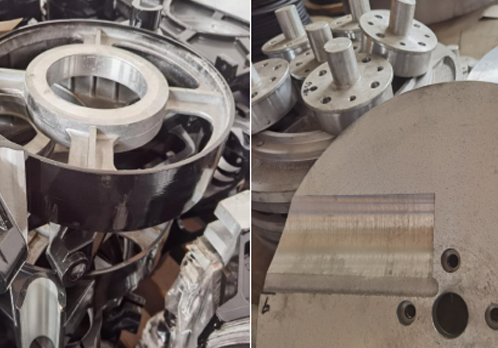

The raw material quality inspection mainly is the bracket inspection and the chip inspection Control the raw material quality inspection, Minimize risks, save costs and time, and ensure quality to your final customers.

For the processed parts, we will strictly follow the drawing size to check, as well as the weight and layer surface, whether there is shoddy workmanship.

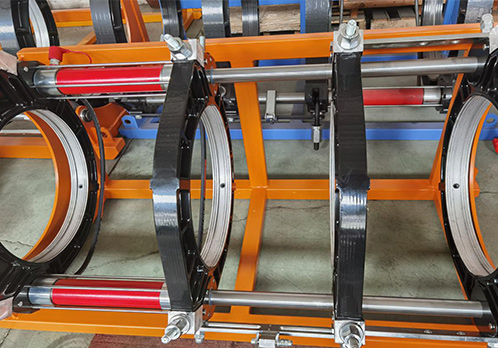

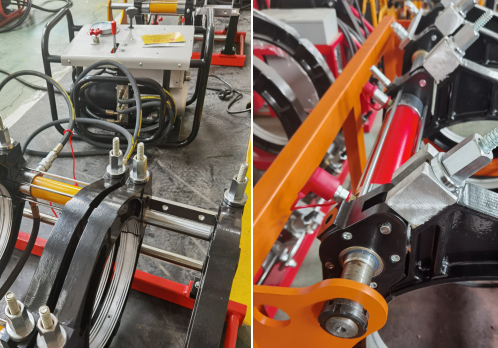

The most important part is assembly control. All the employees involved in assembly are experienced masters in assembly, and they are also trained by our technical engineers. After the whole machine is assembled, we repeatedly test the machine and weld the pipes. Find the problem and solve it in time to ensure that there is no problem after leaving the factory.

As a butt welding machine manufacturer, we are aware of our responsibility for the Welding Industry. Not only do we manufacture and supply some of the best PE pipe welding machine on the market, but we also offer international training and advice – so our clients know they've got on-ground support to ensure a premium outcome, every time, everywhere. In addition, we get involved with social and environmental projects in our region. In the face of the recent novel coronavirus, we actively donated to the disaster areas, but also to our customers as far as possible to send some protective materials.